Wheel Calibration

Contents

Wheel Calibration#

This chapter describes how to perform the kinematics calibration procedure for your Duckiebot.

What you will need

Completed .

What you will get

A Duckiebot with calibrated kinematics.

This wheel calibration is required to make a Duckiebot go straight when commanded to do so.

Introduction to wheel calibration#

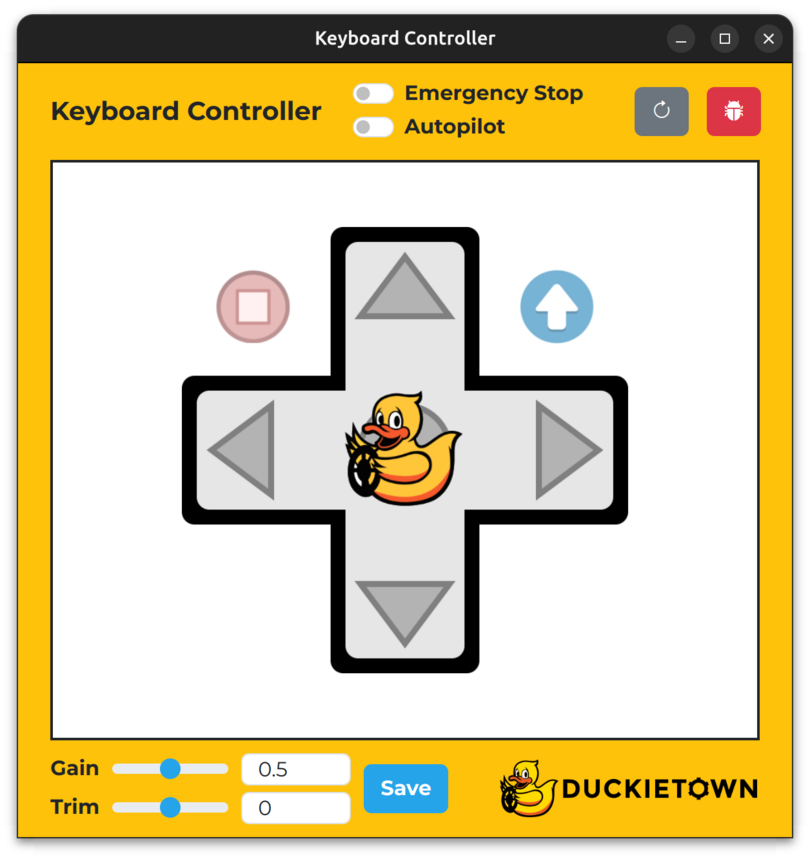

To perform the kinematics calibration procedure for your Duckiebot is by using the Keyboard Controller.

Fig. 41 The Duckiebot keyboard controller is useful to easily open loop control a connected Duckiebot, as well as for adjusting the wheel calibration parameters.#

To open the Keyboard Controller, run:

dts duckiebot keyboard_control DUCKIEBOT_NAME

Note the keys in the table below.

Key |

Function |

|---|---|

W |

Drive forwards |

S |

Drive backwards |

A |

Turn left |

D |

Turn right |

E |

Toggle the |

F |

Toggle the |

X |

Increase the |

Z |

Decrease the |

V |

Increase the |

C |

Decrease the |

Space |

Save the |

R |

Refresh the window |

T |

Open the |

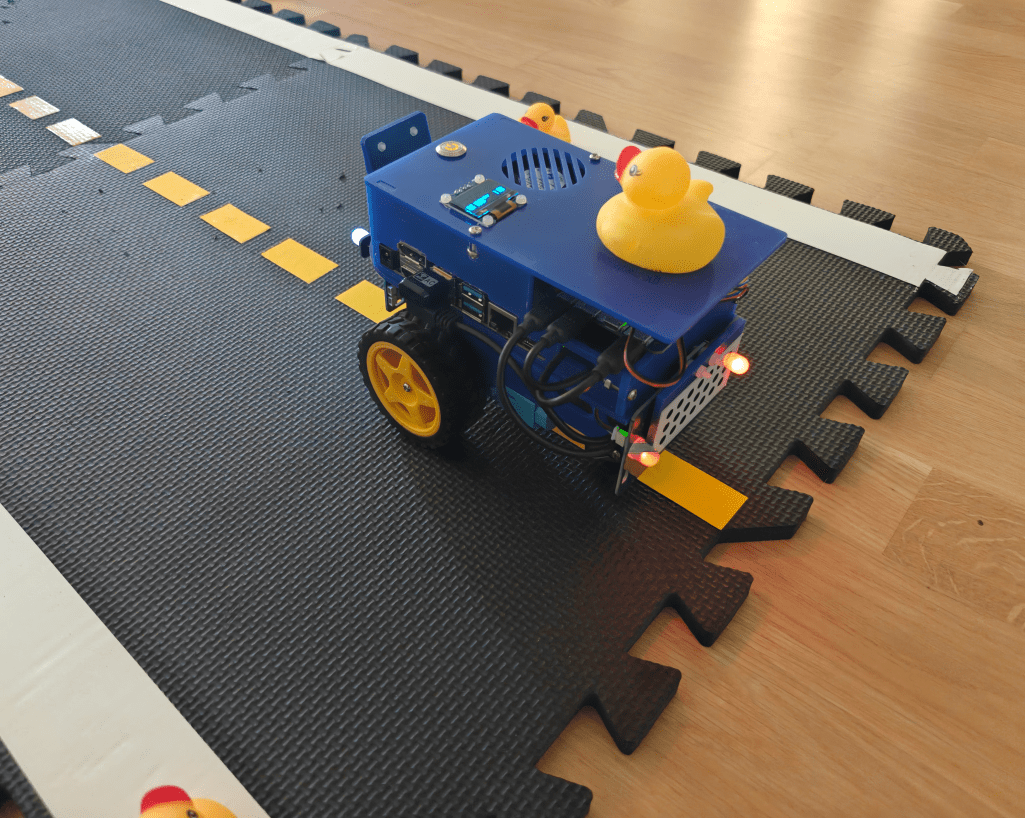

Procedure#

To perform the kinematics calibration procedure:

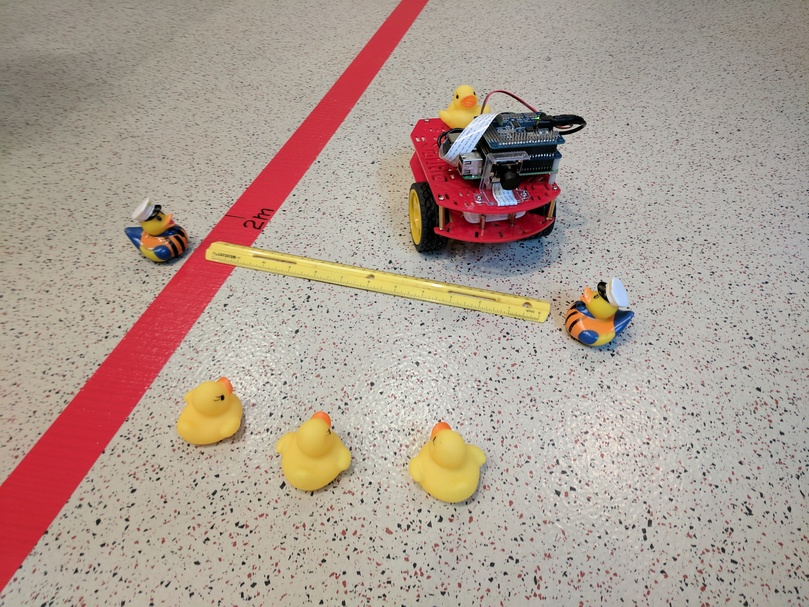

Create a slightly greater than

2 mlong straight line on your floor using tape (or 4 straight tiles, each one is60 cmlong)Place your Duckiebot at one end of the line

Note your Duckiebot’s position

Face your Duckiebot towards the other end of the line

Drive your Duckiebot forward for about

2 mNote your Duckiebot’s position

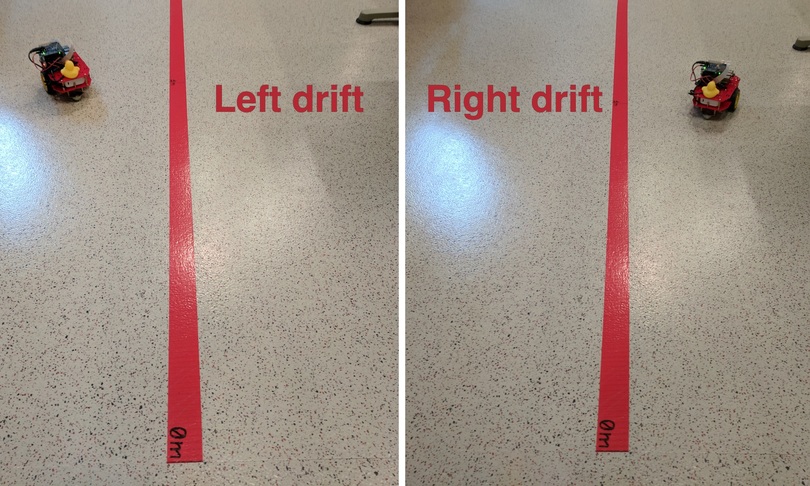

Measure the distance between the center of the tape and the center of your Duckiebot’s axle using a ruler, making sure that the ruler is perpendicular to the tape

Decrease (increase) the

Trimand repeat steps 2-8 if your Duckiebot drifted to the left (right) side of the tape by more than10 cm.Set the

Gain.Click the

Savebutton.

Fig. 42 Mark a straight line on the floor to set a baseline for the Duckiebot kinematics/wheel/odometry calibration procedure.#

Fig. 43 Left/right drift is caused by uncalibrated wheels. Modifying the trim parameter will help correct imperfections.#

Fig. 44 Measure the amount of drift, or deviation from the line, after driving forward for about 2 m, to determine when the calibration is “good enough”.#

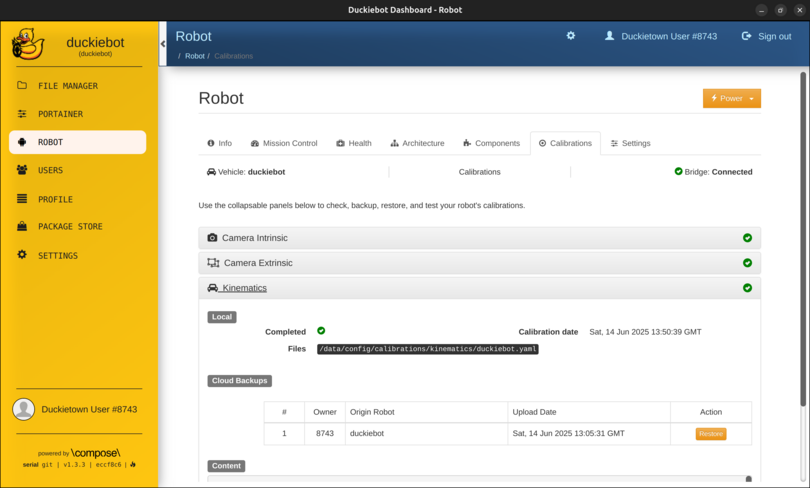

To confirm that a new kinematics calibration file has been created on your Duckiebot, run the following command and inspect the contents of the Kinematics panel:

dts duckiebot dashboard DUCKIEBOT_NAME --page robot/calibrations

Fig. 45 The Kinematics panel on the Robot page of the Dashboard.#

Note

Within the Kinematics panel, under Local, you should see a tick next to Completed, the calibration date next to Calibration date and /data/config/calibrations/kinematics/DUCKIEBOT_NAME.yaml next to Files.